How to Check / Test / Verify Injector Values on Volkswagen Audi Seat Skoda 1.6 1.9 2.0 2.7 3.0 TDI CR and 2.0 FSI TSI TFSI with VCDS.

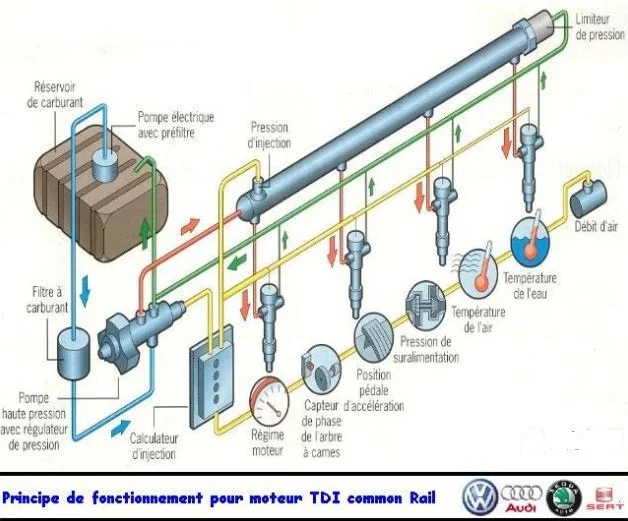

Role and operating principle

Located at the cylinder inlet or in the intake manifold, the injector sprays fuel in microscopic droplets at the end of the compression cycle.

For your car to start, air/fuel combustion must take place. The aim of the injection system is to calculate this fuel/air ratio so that combustion can take place.

The injector then releases the exact quantity of fuel, either directly into the intake manifold in the case of indirect injection (gasoline), or directly into the combustion chamber in the case of direct injection (diesel or gasoline).

Today, injections are managed by an electronic system, which improves engine performance and reduces fuel consumption and pollutant toxins released by the exhaust.

Causes of clogging

In principle, an injector has a fairly long service life. However, clogging problems are common. The cause is fuel quality, as well as scale and resin deposits caused by combustion, which end up clogging the injectors, reducing engine performance and increasing fuel consumption.

Symptoms of a clogged injector

A clogged injector often manifests itself through the following symptoms:

- loss of engine power

- black exhaust smoke

- higher fuel consumption

- capricious slow motion

- a difficult start

- a persistent fuel smell

- acceleration holes

If your vehicle shows these symptoms, then your injectors are most likely clogged. However, before you consider replacing them, you need to check them with the VCDS to find out which one is faulty. VAG Coding offers you several tutorials depending on your TDI or TSI engine:

Contents:

- Injector inspection 1.6 1.9 2.0 TDI

- Injector control / High Pressure Rail 2.0 FSI TSI TFSI

- Injector inspection 2.7 / 3.0 V6 TDI Common Rail

-> VCDS: Adaptation of Common Rail injector correction value

-> VCDS: Turbo pressure control

-> VCDS : FAP regeneration

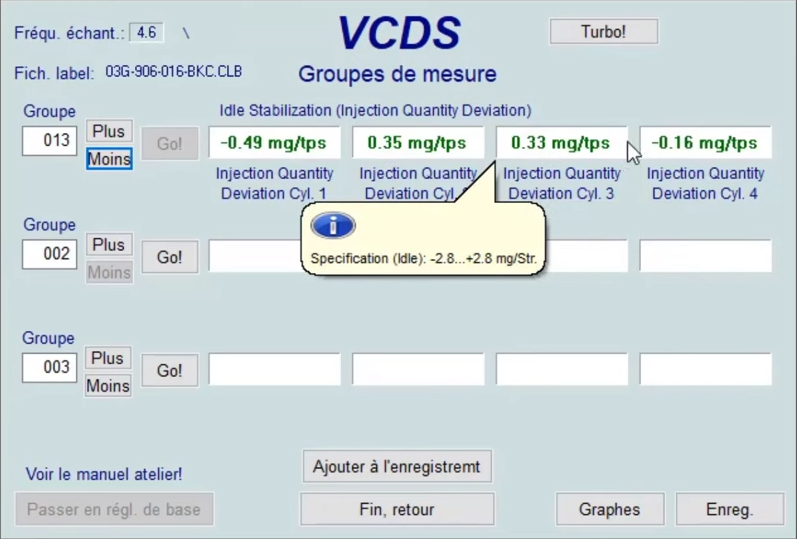

Injector inspection 1.6 1.9 2.0 TDI:

Control for 1.9 TDI and 1.6 / 2.0 TDI CR Common Rail diesel engines (VW Golf 5/6, Polo 4/5, Audi A3 8P, Seat ibiza 6L/6P, Leon …)

Proceed :

1 – Engine off, ignition off, connect your official VAG-COM VCDS cable to

the computer, then plug the other end into your vehicle’s diagnostics socket.

2 – Switch on the ignition and run the VCDS program.

3 – Click on“Select”, then click on“01 – Motor”.

4 – Click on“Measurement group – 08”.

5 – Select Group 013

At idle, a flow correction is applied to each injector in relation to a theoretical flow rate to ensure cyclic engine smoothness.

A flow rate deviation of more than +1.5mg/ stroke is considered abnormal, but not necessarily entirely attributable to the injector. (+ 2.8 mg/tps = injector out of order)

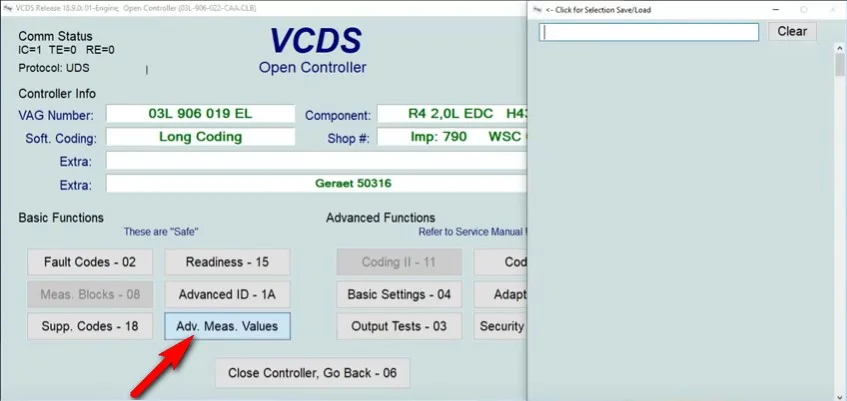

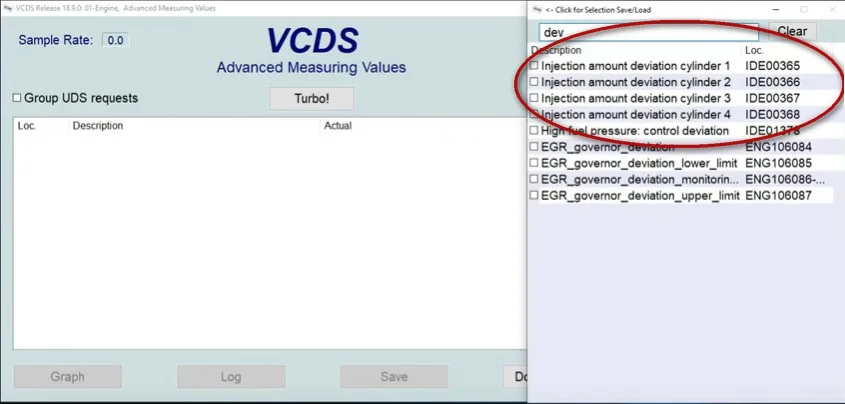

If“Measurement group – 08” is greyed out, click on “Mes. Advanced Values”, then search for “injection” / “deviation” in the search bar, and select the lines according to your cylinders.

Injector control / High Pressure Rail 2.0 FSI TSI TFSI

Checking the injection of the 2.0 EA113 engine, our High Pressure Rail test tutorial. This test will tell you if you have a leaking injector.

A leak in the high-pressure injection rail on our 2.0 TSI TFSI engine could cause a number of different problems for your engine. Our TSI TFSI engine features high-pressure injectors, and they must not be neglected!

For 2.0 on VW GOLF 5 / 6 / 7 GTI, VW GOLF 6R 7R or Audi S3 8P 8V …

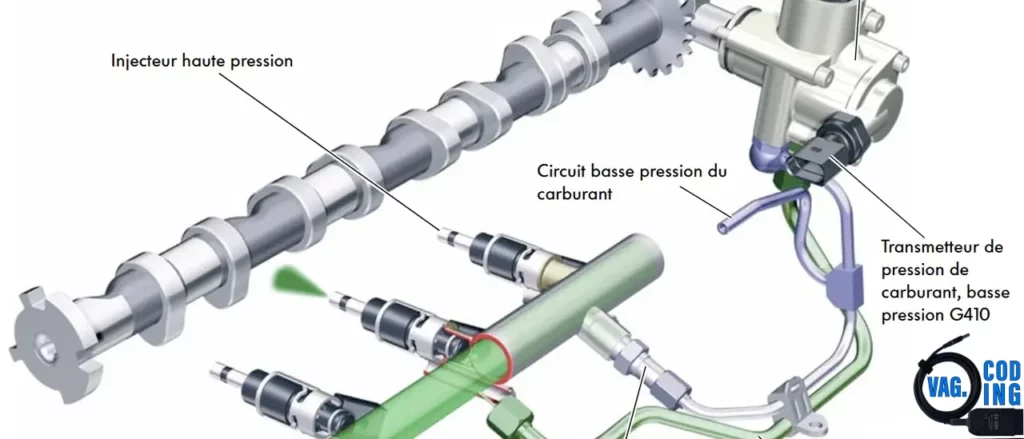

A reminder of how an injector works

The injector is part of your engine’s fuel supply system. The injectors on our TFSI engine are high-pressure injectors, which operate in direct injection mode (fuel is injected directly into the combustion chamber).

Please note that we’re talking here about direct fuel injection with the Bosch Motronic MED 9.1 system (for our EA113 engine), but that this article applies in general to all engines using the group’s high-pressure injection system: FSI, TFSI or TFSI.

It’s the injector that releases the jet of fuel needed to feed the engine, also known as mist or vaporization.

How an injector works

During injection, the magnetic coil built into the injector is driven, creating a magnetic field. This excites the magnetic armature via a needle, the valve opens and fuel is injected (vaporized).

If the coil is no longer energized, the magnetic field collapses and the valve needle is pushed back into the valve seat by the pressure spring. Fuel flow is interrupted.

Injector components

- the injector nose consists of a nozzle sealed by a needle

- the upper part of the injector contains an electromagnetic core, controlled by the ECU, which raises the needle for injection.

Injection time

Secondly,injection duration is an important criterion for our engine, as is its cc capacity. The duration of this jet, also known as injection time, is controlled electrically by the engine management ECU, according to parameters read by sensors (engine temperature, accelerator pedal position, engine load determined by intake air pressure, etc.).

Causes of injector leakage

We often wonder why an injector can leak, and it’s a very good question.

On our TFSI engine, there are various “injection system failures”, some of which are due to impurities clogging an injector, resulting in a leak, as either :

- they prevent the injector from closing properly (leakage)

- they prevent fuel from flowing properly (clogged injector)

The fuel filter, even if you run on SP98, should be replaced every 60,000kms, according to the maintenance schedule.

However, in view of the feedback and observations on the various forums and groups, we strongly recommend replacing it every 30,000kms!

The consequences of a leaking injector

A leaking injector will hinder the proper operation of your injection system, and may even deteriorate it to the point of requiring replacement.

It should also be noted that a leaking injector can cause olfactory and respiratory nuisance for vehicle users, who breathe in fuel and oil vapors, and even more toxic fumes such as carbon monoxide.

Other consequences:

- oil pollution with petrol, so the engine oil no longer lubricates the engine properly

- oil level rises, leading to engine/turbo failure

- combustion misfires

- unbalanced load distribution between engine cylinders

How to detect injector failure

A malfunction can be detected by a number of indicators:

- A lingering smell of fuel

- A loss of power

- Start-up problems

- jerky acceleration

- Smoke in the exhaust

- A smell of gasoline if you open the oil filler cap

- Missed after big sessions, the engine backfires a bit like a Pop & Bang.

When an injector malfunctions on an FSI / TSI / TFSI engine, you can expect combustion misfires. This is the most common phenomenon.

Fault codes may include: P0300, P0301 (for cylinder 1), P0302 (for cylinder 2), P0303 (for cylinder 3), P0304 (for cylinder 4).

You’ll probably only get misfiring on 1 or 2 cylinders, as it’s unlikely that all 4 injectors will be faulty at the same time (unless your injectors are counterfeit …)

Generally, when these fuel injectors are faulty, they get stuck, causing misfire problems.

Before assuming you have a fuel injector problem, you need to confirm that you do NOT have problems with the following, ignition coils, spark plugs (change every 40-60K) or carbon build-up, but we’ll see that it’s possible to test the injector RAIL too.

All the faults listed are more likely to cause misfiring. Once you’ve checked that none of these is a problem, you need to turn your attention to the injectors.

How do I test an injector leak at the VCDS?

Now, let’s see how you can test your injectors, without dismantling anything. This test will enable you to identify a leak on the injection rail.

To do this, we will use our VAGCOM cable and VCDS software, once the vehicle is at optimum operating temperature (water at 90c°).

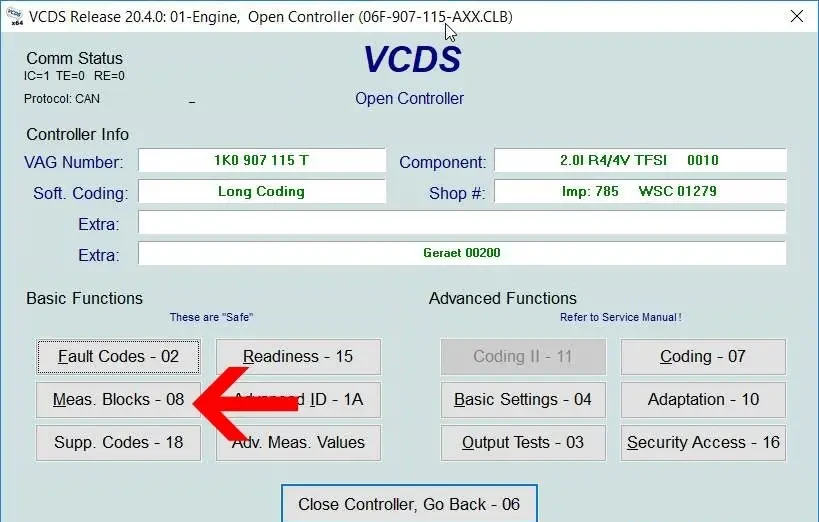

Proceed :

1 – Engine off, ignition off, connect your official VAG-COM VCDS cable to

the computer, then plug the other end into your vehicle’s diagnostics socket.

2 – Switch on the ignition and run the VCDS program.

3 – Click on“Select”, then click on“01 – Motor”.

4 – Click on“Measurement group – 08”.

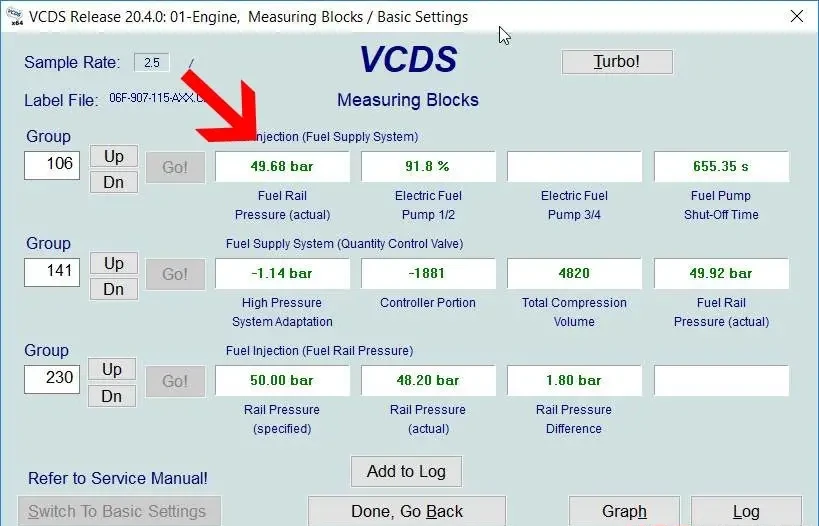

Once on the Measurement blocks tab, select the following channels: 106, 141 and 230.

Our engine is running and we have a pressure of 49.68 bar on the rail.

Wait until the water has reached 90°C, then turn off the ignition.

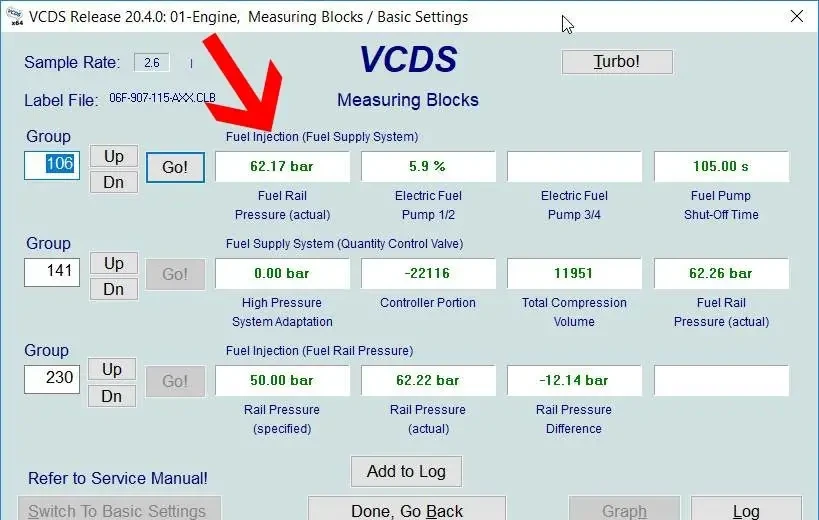

The pressure should increase gradually, as shown here at 62.17 bar.

Now observe the value for a few minutes.

This value should increase significantly!

If it doesn’t (if it doesn’t increase), there must be a leak.

Injector inspection 2.7 / 3.0 V6 TDI Common Rail

For a simple injector check or because you’re having a problem with your V6 TDI, especially after a long drive. The white smoke and shaking you’re seeing could indeed be linked to worn injector seats, which is a valid assumption in this context. Here are some points to consider and possible checks to diagnose and solve the problem:

1. White exhaust smoke

The presence of white smoke can be due to a number of causes. In the context of a diesel engine, here are the possible causes:

- Unburned fuel: As you mentioned, worn injector seats can lead to excessive fuel injection into the combustion chamber. This excess fuel may not burn completely, producing white smoke. This smoke is generally the result of incomplete diesel combustion.

- Cooling problems: Another potential cause is a problem with the cooling system, such as a faulty cylinder head gasket. This can allow cooling water to enter the combustion chambers, also producing white smoke. If this is the case, you may also see signs of coolant loss or bubbles in the coolant.

2. Engine shaking

Shaking, especially at idle after prolonged operation, can be related to several problems:

- Faulty injectors: Worn or faulty injectors can cause shaking due to irregular fuel injection. Worn injector seats can lead to leaks or incorrect atomization, which can cause engine vibration.

- Combustion problems: Poor fuel combustion due to faulty injectors can also lead to jerking and reduced idle smoothness.

To assess the condition of your vehicle’s injectors using measurement value blocks 72 to 77 with a diagnostic tool such as VAG-COM (or VCDS), here’s a detailed guide to interpreting the values and detecting possible problems:

Reading Measurement Block Values

Proceed :

1 – Engine off, ignition off, connect your official VAG-COM VCDS cable to

the computer, then plug the other end into your vehicle’s diagnostics socket.

2 – Switch on the ignition and run the VCDS program.

3 – Click on“Select”, then click on“01 – Motor”.

4 – Click on“Measurement group – 08”.

5 – Select measurement groups 72 to 77.

6 – Interpretation of Values: Each measurement group will display three values corresponding to different pressure levels (300 bar, 600 bar, 1,000 bar). Values are in milliseconds (ms) and should be read carefully.

Results analysis

For each measurement group, examine the values and compare them with the indicated thresholds. Here’s how to interpret the values provided:

Group 72

- Values: -50 ms, -14 ms, -6 ms

- Analysis: The first value (-50 ms) is below the threshold of -45 ms, which may indicate significant needle seat wear for the corresponding injector.

Group 73

- Values: -24 ms, -4 ms, -2 ms

- Analysis: None of the values exceed critical thresholds. Injectors appear to be in good condition.

Group 74

- Values: -24 ms, -4 ms, -6 ms

- Analysis: None of the values exceed critical thresholds. Injectors appear to be in good condition.

Group 75

- Values: -54 ms, -12 ms, -6 ms

- Analysis: The first value (-54 ms) exceeds the critical threshold of -45 ms, which may indicate significant needle seat wear.

Group 76

- Values: -36 ms, -6 ms, -6 ms

- Analysis: None of the values exceed critical thresholds. Injectors appear to be in good condition.

Group 77

- Values: -48 ms, -12 ms, -6 ms

- Analysis: The first value (-48 ms) exceeds the critical threshold of -45 ms, which may indicate significant needle seat wear.

Conclusion and actions

- Defective injectors: Excessive negative values (e.g. -50 ms, -54 ms, -48 ms) indicate that some injectors may be defective due to needle seat wear.

- Replacement: We recommend replacing the offending injectors to improve engine performance.

Summary of Critical Thresholds :

- First Pressure Level (300 bar): Value below -45 ms (e.g. -60 ms) indicates wear.

- Second Pressure Level (600 bar): Value below -15 ms (e.g. -20 ms) indicates wear.

Important notes:

- Attention to the Sign (Minus): Values are negative, so a more negative value indicates a more serious problem.

- Precise Interpretation: Make sure you understand the values and thresholds before making decisions about injector replacement.

This process will enable you to correctly diagnose your vehicle’s injectors and take the necessary steps to ensure their proper operation.

-> VCDS: Injector replacement and IMA code adaptation on 2.7 / 3.0 V6 TDI Common Rail engines